Advantages of Anodizing, Chromate, and Black Oxide

Advantages of Anodizing, Chromate, and Black Oxide

As a plating company specializing in anodizing, chromate, zinc, and black oxide plating for the aerospace and defense industry, we understand the unique requirements of these industries. In this page, we will discuss the specific advantages of our plating processes for aerospace and defense manufacturers.

Anodizing

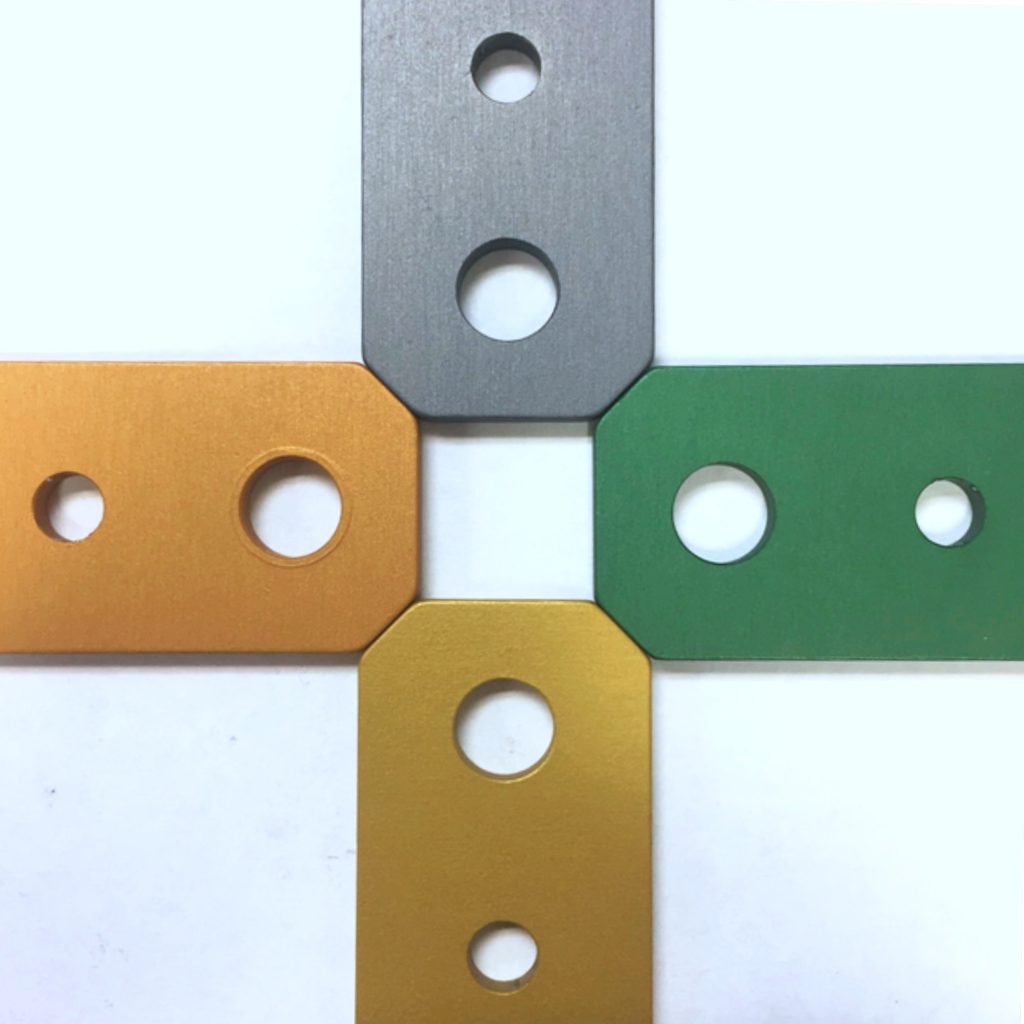

Anodizing provides excellent corrosion resistance and durability, which are essential for aerospace and defense applications. The protective oxide layer created by anodizing improves the wear and tear resistance of aluminum parts, making them suitable for harsh environments. Additionally, anodizing can enhance the appearance of parts, providing a wide range of colors and finishes.

Chromate

Chromate plating is a highly effective way to improve the corrosion resistance and electrical conductivity of aluminum, magnesium, and zinc alloys, which are commonly used in aerospace and defense applications. The chromate coating also enhances the adhesion of paints and other coatings, providing an additional layer of protection against environmental factors.

Passivation

Passivation is a crucial step for defense and aerospace components, as it removes any impurities and free iron from the surface of stainless steel, creating a clean, corrosion-resistant layer that can withstand the harsh environments of aerospace and defense operations, ensuring maximum durability and longevity of the components.

Black Oxide

Black oxide plating is an essential process for defense and aerospace applications as it not only provides a sleek and uniform black finish but also offers superior resistance to corrosion, abrasion, and wear, ensuring that critical parts and components can withstand the harsh environmental conditions and operate reliably and efficiently over extended periods.

Summary

The advantages of anodizing, chromate, zinc, and black oxide plating for manufacturers include superior corrosion resistance, increased durability, improved electrical conductivity, and enhanced aesthetic appeal. Our plating company provides high-quality plating services that meet or exceed industry and government standards and regulations. Contact us today to learn more about how our plating processes can benefit your company.

Questions?

If you have any further questions, please feel free to use the contact form or give us a call at 303-733-4470.